Guaranteeing that offered container–closure platforms are assembled to meet supplied functional and aesthetic demands

If these products and solutions aren't processed aseptically, it could inspire contamination. Sadly, since These are specifically injected into delicate membranes, contaminated merchandise can severely have an affect on the tip person.

Contaminated bottles may be used in subsequent filling. Lot reconciliation is not accurate. Prospect of combine-up. Destructive impact on merchandise good quality. GMP violation and regulatory problem

Publicity of settle plates (petri dishes of nutrient agar) at vital positions in just the final place exactly where the device is sited.

Liquid Option, liquid suspension, powder and lyophilized with their involved filling systems

IVEK features free in-depth Examination to determine the most appropriate fluid managing method in your application.

Filtered compressed air and granules of the plastic materials conforming to some predetermined specification and known to be appropriate With all the products to get crammed (usually polyethylene, polypropylene or polyethylene/polypropylene co-polymers) are provided for the equipment.

All hazards associated with the procedure in issue With this section (Desk two) are evaluated, and RPNs are already identified. Making an allowance for the severity, occurrence, and detection standard of the risk, Desk two presents an example of a hazard that is greater than 104. (purple). The group agreed to acquire the right Handle steps and safeguards to do away with or mitigate the chance, As an illustration, the danger related to getting pictures while in the limited areas and the negative effect of these risk on the company’s personal home and firm private information and also the misuse of taken photos by any means.

Multi Channel Customized devices for just read more about any quantity of channels nearly (24). Provided in either Rotary or Linear dispense methods. Unbiased dispensing parameters is often customized as required with very simple programming.

An in-system Command and monitoring software is necessary for environmental particulates, filter integrity, microbiological worries and product or service Regulate. The environmental air really should be checked to ensure it stays in conformity Together with the specification. The fast air shower surroundings also must conform to requirements through processing with respect to viable and, wherever attainable, nonviable particulate make a difference.

Able to operate in a category one hundred Natural environment. Power to use Aseptic Space gown that includes surgical mask, goggles and comply with gowning validation and subsequent gowning verifications.

The views expressed Here's the sights of the writer and don't essentially reflect the views and viewpoints of News Professional medical. Cancel reply to remark

Relevant SOP really should be revised to cover the usage of a checklist to assure the absence of click here any empty glass bottles inside of bottle washing device all through breaks and at the conclusion of change. The checklist needs to be counter-signed by device supervisor.

An extensive portfolio of normal and personalized tube sets for transfer, distribution or filling of in-process fluids.

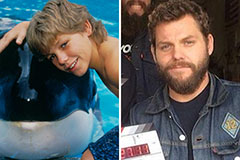

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Jenna Jameson Then & Now!

Jenna Jameson Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!